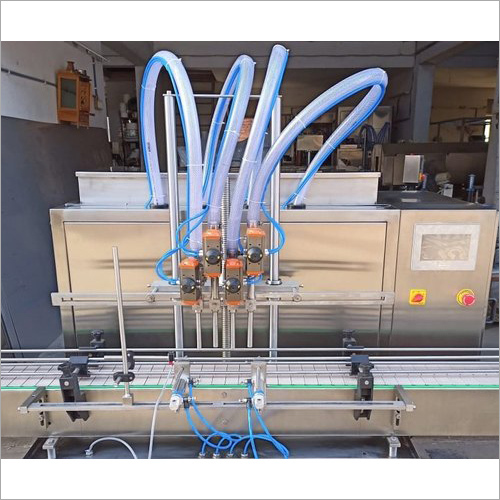

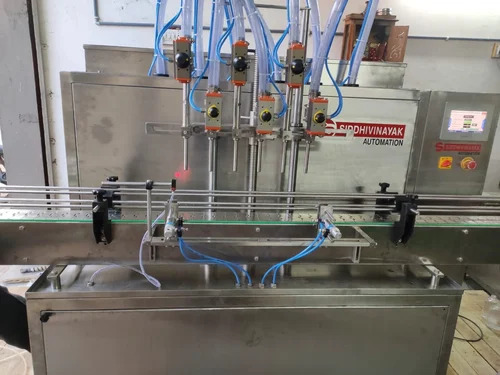

Volumetric Liquid Filling Machine

Price 1 INR/ Piece

Volumetric Liquid Filling Machine Specification

- Material

- Metal

Volumetric Liquid Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Eastern Europe, Central America, Middle East, Western Europe, Asia, North America, Australia, Africa, South America

- Main Domestic Market

- Tamil Nadu, Assam, Himachal Pradesh, Haryana, Central India, Andhra Pradesh, Bihar, Pondicherry, Maharashtra, Chandigarh, Chhattisgarh, Manipur, North India, Karnataka, Odisha, Tripura, Uttar Pradesh, Gujarat, Rajasthan, West India, Kerala, Goa, Madhya Pradesh, Andaman and Nicobar Islands, Sikkim, Dadra and Nagar Haveli, All India, Uttarakhand, Telangana, Delhi, Lakshadweep, Nagaland, Mizoram, Daman and Diu, West Bengal, Arunachal Pradesh, East India, South India, Punjab, Jharkhand, Jammu and Kashmir, Meghalaya

About Volumetric Liquid Filling Machine

SVAVLF100/150/200 works on the principle of volumetric liquid filling with diving nozzles. A volumetric liquid filling machine can fill different viscosity liquids into containers. The stainless steel built filling machine consists of a stainless steel slat conveyor, a reciprocating nozzle with self-cantering devices, and a stainless steel syringe.

The empty containers are conveyed along a movable stainless steel slat conveyor and stopped via a pneumatically or mechanically operated stopper system below the filling nozzles. Filling is accomplished by the filling nozzle beneath the container. Through the use of twin pneumatically operated stopper systems and reciprocating nozzles, it is easy to match the container precisely below the nozzles, avoiding liquid spillage. Liquid doses can easily be adjusted using a hexagonal bolt, which is fitted beneath syringes.

Salient Features of Volumetric Liquid Filling Machine:

- Low power consumption, low noise, and no vibrations.

- 1% filling accuracy for single doses.

- Stylish and easy-to-use control panel for total control of operation.

- Self-lubricating UHMW-PE guide profiles optimize chain wear and ensure smooth conveyance.

- Under the conveyor is a drip tray.

- An arrangement for stopping bottles pneumatically or mechanically.

- Conveyor gear box, motor, and pneumatic cylinders safety guards.

- Nitrogen flushing system provided (Pre or Post) at customer's request.

| Driven Type | Electric |

| Material | Stainless Steel |

| Country of Origin | Made in India |

| No. Of Heads | 8 |

| Capacity | 100 bottle/min |

Optional Features of Volumetric Liquid Filling Machine:

- Conveyor belt chain washing system by automatic means

- Pre-inspection built into the machine.

- Cabinet made from acrylic.

- Flushing with nitrogen.

- Holding tank for flotation

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Shampoo Filling Machine

Price 1750000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Feature : Other, High accuracy, Adjustable filling volume, No drip nozzle

Weight (kg) : Approx. 350 kg

Material : Stainless Steel (SS304/SS316)

Computerized : Yes

Automatic Servo Liquid Filling Machine

Price 690000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, High Filling Accuracy, No Dripping, Fast Changeover

Weight (kg) : Approx. 650 kg

Material : Stainless Steel (SS304/SS316)

Computerized : Yes

Juice Filling Machine

Feature : Other, HighSpeed Filling, Drip Free Operation, Automatic Bottle Alignment

Weight (kg) : Approx. 1200 kg

Material : Stainless Steel (SUS304/SUS316)

Computerized : Yes

Fully Automatic 4 Head Volumetric Liquid Filling Machine

Feature : Other, Automatic Stop and Start, No Bottle No Fill System, DripFree Nozzles, UserFriendly Interface

Weight (kg) : Approx. 400 kg

Material : Stainless Steel (SS 304/316)

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free