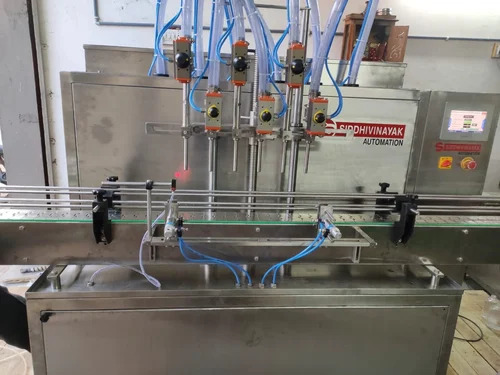

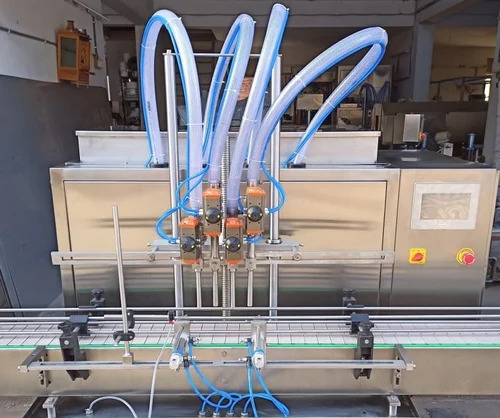

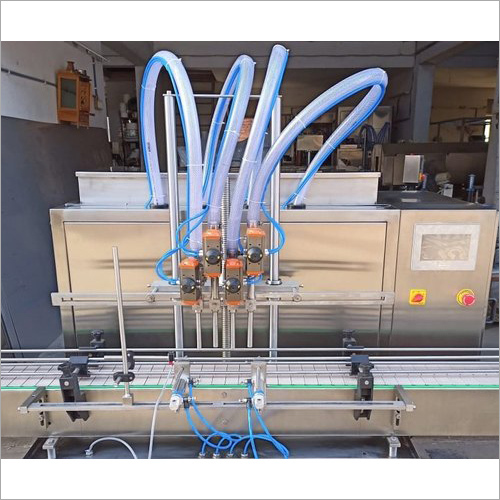

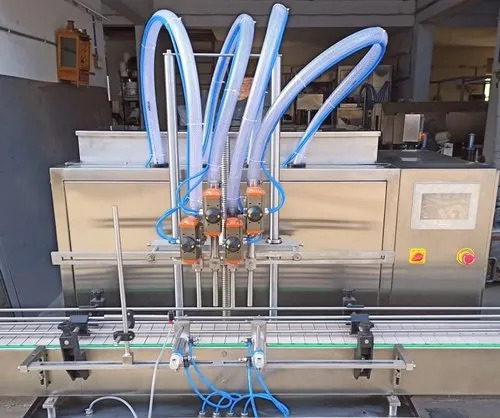

Juice Filling Machine

Juice Filling Machine Specification

- Product Type

- Juice Filling Machine

- Material

- Stainless Steel (SUS304/SUS316)

- Application

- Juice Beverage Production

- Packaging Material

- PET/Glass Bottles

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 220-380 V AC

- Weight (kg)

- Approx. 1200 kg

- Dimension (L*W*H)

- 2500 mm 1800 mm 2200 mm

- Capacity

- 2000-12000 bottles per hour

- Feature

- High-Speed Filling, Drip Free Operation, Automatic Bottle Alignment

- Color

- Silver Metallic

- Filling Accuracy

- ±1%

- Noise Level

- <70 dB

- Cleaning System

- CIP (Clean-in-Place) Supported

- Touch Screen Interface

- 7 inch full color HMI

- Bottle Size Range

- 200 ml - 2000 ml

- Power Consumption

- 3-7 kW (depends on model)

- Air Pressure Requirements

- 0.6-0.8 MPa

- Rinsing-Filling-Capping

- Integrated 3-in-1 System

- Main Motor Brand

- Siemens/Equivalent

- Conveyor Type

- Modular Chain Conveyor

- Filling Heads

- 8/12/16/24 Customizable

Juice Filling Machine Trade Information

- Supply Ability

- 100 Per Week

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Juice Filling Machine

Premier Solution for Juice Production

The Juice Filling Machine is ideal for large-scale juice beverage production lines, commonly used by manufacturers, suppliers, and exporters in India. Its advanced automation and supreme filling accuracy make it suitable for PET and glass bottle applications in commercial processing plants, guaranteeing efficient bottle alignment and high-speed operation. The machine's stainless steel structure offers long-term reliability, reducing labor and maximizing throughput for businesses seeking superior productivity.

Quotation & Shipping Policy for Your Orders

Quotation requests are promptly processed, with stock ready for immediate shipment from our FOB port in India. We maintain readily available machines for fast loading and delivery, minimizing lead times for shipped goods. Our payment terms are flexible, supporting securities like LC, TT, and more, making transactions smooth for suppliers, exporters, and overseas buyers. Engage with us for details on sample policy and ensure hassle-free procurement as you plan to enhance your beverage bottling operations.

FAQ's of Juice Filling Machine:

Q: How does the Juice Filling Machine ensure precise filling for different bottle sizes?

A: The Juice Filling Machine utilizes a computerized PLC control system and customizable filling heads, allowing accurate liquid dispensation for bottle sizes ranging from 200 ml to 2000 ml. Its 1% filling accuracy ensures consistency across all batches.Q: What is the process for integrating the machine into an existing production line?

A: Integration is straightforward due to the modular chain conveyor and automated bottle alignment feature. The machine's standardized dimensions and electric drive allow seamless addition to most commercial bottling setups, with adaptable interface options.Q: Where is the ideal site of application for this filling machine?

A: This machine is best suited to beverage production facilities, juice factories, and plants handling PET or glass containers. It's commonly installed by exporters, manufacturers, and suppliers in industrial settings.Q: When can I expect delivery after placing an order?

A: Shipment timelines are fast due to stock readiness. Once your quotation is accepted and payment terms confirmed, goods are dispatched promptly from the Indian FOB port, ensuring minimal delay for your operational needs.Q: What advantages does the CIP-supported cleaning system provide?

A: The built-in Clean-in-Place (CIP) system supports automated, hygienic cleaning, reducing downtime, ensuring food safety compliance, and facilitating quick transitions between production cycles for different beverage batches.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Shampoo Filling Machine

Price 1750000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Stainless Steel (SS304/SS316)

Feature : Other, High accuracy, Adjustable filling volume, No drip nozzle

Application : Other, Shampoo, Lotion, Liquid Soap, Hair Oil

Color : Silver

Automatic Servo Liquid Filling Machine

Price 690000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel (SS304/SS316)

Feature : Other, High Filling Accuracy, No Dripping, Fast Changeover

Application : Other, Pharmaceuticals, Cosmetics, Food & Beverages, Chemicals

Color : Other, Silver/Grey

Dry Syrup Filling Machine

Material : Stainless Steel (SS 304/316)

Feature : Other, High Accuracy Filling, Simple Operation, Easy Cleaning

Application : Other, Dry Powder Filling in Bottles/Jars

Color : Other, Silver/Grey (Stainless Steel Finish)

Fully Automatic 4 Head Volumetric Liquid Filling Machine

Material : Stainless Steel (SS 304/316)

Feature : Other, Automatic Stop and Start, No Bottle No Fill System, DripFree Nozzles, UserFriendly Interface

Application : Other, Liquid Filling for Pharmaceuticals, Food & Beverage, Chemicals, Cosmetics

Color : Other, Silver (Stainless Steel Finish)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free