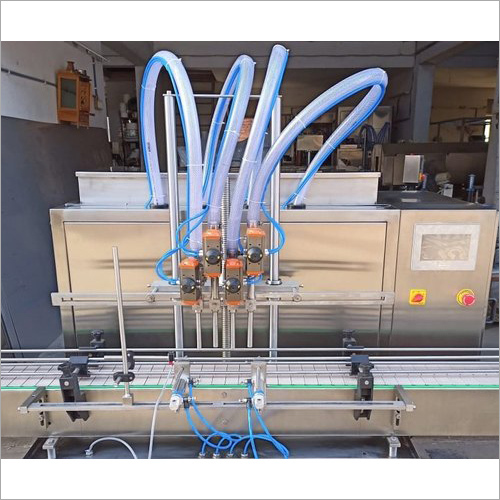

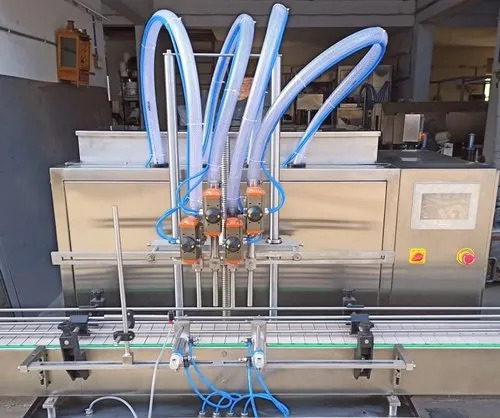

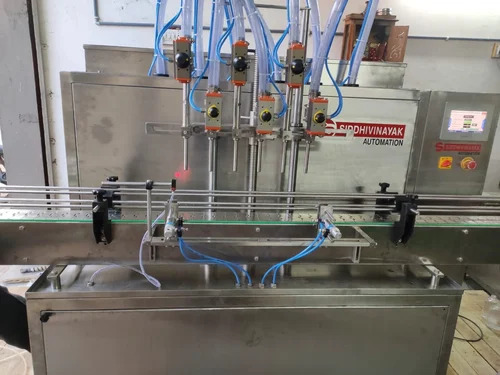

Automatic Servo Liquid Filling Machine

Price 690000 INR/ Piece

Automatic Servo Liquid Filling Machine Specification

- Product Type

- Automatic Servo Liquid Filling Machine

- Material

- Stainless Steel (SS304/SS316)

- Application

- Pharmaceuticals, Cosmetics, Food & Beverages, Chemicals

- Packaging Material

- PET Bottles, Glass Bottles, Plastic Containers

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Servo Motor

- Voltage

- 220V/380V

- Weight (kg)

- Approx. 650 kg

- Dimension (L*W*H)

- 2200 mm x 1250 mm x 2100 mm

- Capacity

- 30-120 Bottles/Min (Depending on Filling Volume and Container Type)

- Feature

- High Filling Accuracy, No Dripping, Fast Changeover

- Color

- Silver/Grey

- Conveyor Speed

- Adjustable

- Number of Filling Heads

- 4/6/8/12 (Customizable)

- Filling Accuracy

- 0.5%

- Touchscreen Interface

- Yes, 7-inch HMI

- Cleaning System

- CIP (Clean-In-Place) Compatible

- Bottle Diameter Range

- 30100 mm

- Air Pressure

- 0.60.8 MPa

- Noise Level

- < 75 dB

- Power Consumption

- 2.2 kW

- Filling Range

- 50 ml 5000 ml (Adjustable)

- Operating Temperature

- 5C40C

- Filling Nozzle Type

- Anti-drip, Diving Type

- Safety Features

- Emergency Stop, Overload Protection, Fault Alarm

Automatic Servo Liquid Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Africa, Western Europe, Middle East, Australia, Eastern Europe, South America, North America, Asia, Central America

- Main Domestic Market

- Gujarat, Uttar Pradesh, Tripura, North India, Chhattisgarh, Manipur, Odisha, Karnataka, Maharashtra, Chandigarh, Bihar, Pondicherry, Andhra Pradesh, Central India, Himachal Pradesh, Haryana, Assam, Tamil Nadu, Meghalaya, Jammu and Kashmir, Jharkhand, Punjab, South India, East India, Arunachal Pradesh, West Bengal, Mizoram, Daman and Diu, Delhi, Nagaland, Lakshadweep, Telangana, All India, Dadra and Nagar Haveli, Uttarakhand, Sikkim, Andaman and Nicobar Islands, Goa, Madhya Pradesh, West India, Kerala, Rajasthan

About Automatic Servo Liquid Filling Machine

| Capacity | 90 BPM |

| Warranty | 1 year |

| Driven Type | Electric |

| Voltage | 230 V |

| Power | 4 HP |

| Filling Accuracy | +/-1% |

| Brand | Siddhivinayak Engineering |

| Frequency | 50 Hz |

| Country of Origin | Made in India |

Unmatched Filling Accuracy

Achieve consistent and reliable liquid filling with our machine's precision-driven servo motor and anti-drip nozzle design. Whether dispensing small doses or larger containers, you can trust in an error margin of just 0.5%, ensuring minimal product wastage and high-quality output.

Versatile and Customizable Performance

Easily adjust the filling range and number of filling heads to meet diverse production requirements. The machine supports bottles and containers with diameters from 30 mm to 100 mm, and accommodates various industries, including pharmaceuticals, cosmetics, food & beverages, and chemicals. Extensive compatibility ensures smooth integration into existing lines.

Intuitive Touchscreen Control

Enjoy seamless operation with the integrated 7-inch touchscreen HMI and PLC control system. Adjust parameters, monitor real-time performance, and respond swiftly to alerts. Enhanced safety features, including emergency stop and overload protection, create a secure working environment for operators.

FAQ's of Automatic Servo Liquid Filling Machine:

Q: How does the automatic servo liquid filling machine ensure high filling accuracy?

A: The machine uses a servo motor and PLC control system to precisely measure and dispense liquids, achieving a filling accuracy of 0.5%. The anti-drip, diving-type nozzles further prevent leakage during filling, ensuring consistent and high-quality results across all bottles.Q: What is the cleaning process for this filling machine?

A: Cleaning is straightforward thanks to the CIP (Clean-In-Place) compatibility. With this system, internal components are efficiently cleaned without the need for disassembly, reducing downtime and maintaining hygiene-a crucial benefit for pharmaceutical and food applications.Q: Where can this liquid filling machine be used?

A: It is widely used in pharmaceutical, cosmetic, food & beverage, and chemical industries, making it suitable for filling PET bottles, glass bottles, and plastic containers. Its stainless steel build complies with hygiene standards required in these sectors.Q: When should I adjust the filling heads and conveyor speed?

A: Adjust the number of filling heads and conveyor speed based on batch size, bottle diameter, and desired production rate. These customizable features allow you to optimize throughput, handle different container types, and meet specific production demands quickly.Q: What are the safety features included in the machine?

A: The machine incorporates emergency stop functionality, overload protection, and fault alarms. These features help safeguard operators, prevent equipment damage, and minimize the risk of accidents during operation.Q: How is the machine operated and monitored?

A: Operation is managed via a 7-inch touchscreen HMI panel, enabling intuitive parameter setting and real-time system monitoring. The computerized, automatic grade control ensures streamlined processes and quick fault detection.Q: What are the benefits of using this machine for high-volume packaging?

A: Benefits include rapid changeover, consistent accuracy, reduced product loss (no dripping), safe and quiet operation (<75 dB), CIP compatibility for easy cleaning, and robust performance in demanding production environments. These features maximize productivity and reduce downtime, ideal for high-volume manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Shampoo Filling Machine

Price 1750000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Stainless Steel (SS304/SS316)

Voltage : 220240 V

Computerized : Yes

Feature : Other, High accuracy, Adjustable filling volume, No drip nozzle

Dry Syrup Filling Machine

Material : Stainless Steel (SS 304/316)

Voltage : 220 V / 380 V

Computerized : Yes

Feature : Other, High Accuracy Filling, Simple Operation, Easy Cleaning

Glass Bottle Filling Machine

Material : Stainless Steel

Voltage : 220380 V

Computerized : Yes

Feature : Other, High Precision Filling, Easy Operation, Low Maintenance

Juice Filling Machine

Material : Stainless Steel (SUS304/SUS316)

Voltage : 220380 V AC

Computerized : Yes

Feature : Other, HighSpeed Filling, Drip Free Operation, Automatic Bottle Alignment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free