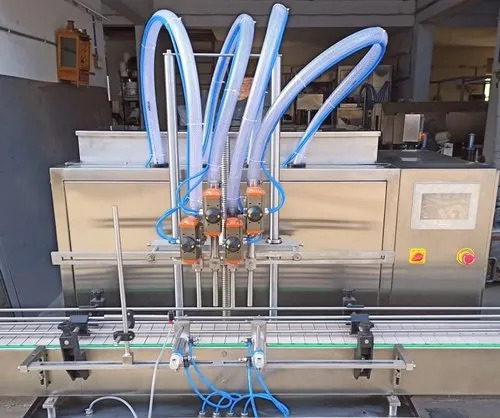

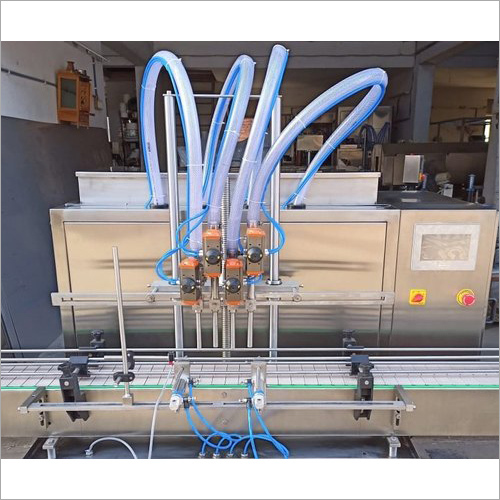

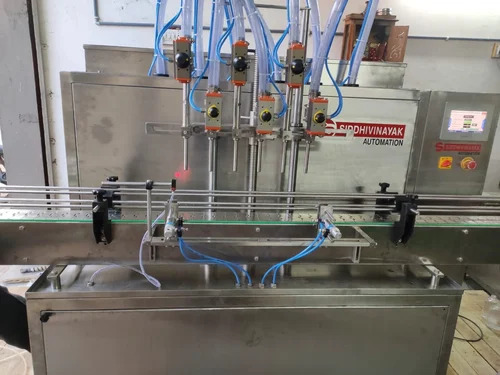

Shampoo Filling Machine

Price 1750000 INR/ Unit

Shampoo Filling Machine Specification

- Product Type

- Shampoo Filling Machine

- Material

- Stainless Steel (SS304/SS316)

- Application

- Shampoo, Lotion, Liquid Soap, Hair Oil

- Packaging Material

- Bottles, Plastic Containers

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control System

- Drive Type

- Electric

- Voltage

- 220-240 V

- Weight (kg)

- Approx. 350 kg

- Dimension (L*W*H)

- 2000 mm x 800 mm x 1850 mm

- Capacity

- 20-60 bottles per minute

- Feature

- High accuracy, Adjustable filling volume, No drip nozzle

- Color

- Silver

Shampoo Filling Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Shampoo Filling Machine

Filling range of this Shampoo Filling machine is between 50 ml to 2000 ml. Made of stainless steel, its working capacity is between 60 to 240 bottles in every minute. The operator needs to place containers non-automatically below its filling nozzles. Shampoo is filled as per pre determined volume. This machine has around four filling heads, PLC controller, servo motor, SS 304/316 grade stainless steel contact parts and pneumatic accessories. User friendly operating interface is one of its key aspects. Most of the components of this Shampoo Filling machine belong to renowned brands of international repute.

| Capacity | 60-120 BPM |

| Machine Type | Semi-Automatic |

| Machine Type | Automatic |

| Voltage | 420 Volt |

| Brand | Siddhivinayak Automation |

| Power Consumption | 3 Hp |

| Volume Simplex | Up to 1 Ltr |

| Frequency | 50Hz |

Advanced Filling Precision

The piston or servo-based volumetric filling principle provides excellent accuracy, with a deviation margin of only 1%. Adjustable filling heads and volume settings ensure consistency and minimize product wastage, lending dependable results in every production cycle.

Flexible Bottle Handling

This machine is compatible with a variety of bottle types, including round, flat, square, and oval designs, as well as multiple packaging materials like plastic containers. Its anti-drip, shut-off nozzles prevent leakage, supporting clean, efficient operations for diverse packaging needs.

User-Friendly & Safe Operations

Powered by a robust PLC control system, this filling machine supports a multilingual HMI for global usability. It features overload protection, an emergency stop function, and Clean-in-Place (CIP) compatibility for safe, easy maintenance. These attributes combine to create a highly reliable and operator-friendly solution.

FAQs of Shampoo Filling Machine:

Q: How does the shampoo filling machine maintain high accuracy during operation?

A: This machine utilizes a piston or servo-based volumetric filling principle, delivering filling accuracy within 1%. The system ensures target volumes are dispensed consistently, helped by PLC controls and precision-engineered components.Q: What types of bottles and packaging can the machine handle?

A: The shampoo filling machine is designed to support round, flat, square, and oval bottles made from plastic or similar container materials. It adapts seamlessly to various shapes and sizes within the 50ml to 1000ml filling range.Q: When should the Clean-in-Place (CIP) system be used, and how does it benefit cleaning?

A: The CIP system should be activated during scheduled maintenance or product changeover. It allows for efficient, automated internal cleaning of machine parts, reducing manual effort and downtime while maintaining hygiene.Q: Where can this machine be installed, and what utilities are required?

A: The filling machine is suitable for manufacturing plants or production facilities and requires a power supply of 220-240V, air pressure of 0.6-0.8 MPa, and sufficient floor space for its 2000 mm x 800 mm x 1850 mm dimensions.Q: What is the process flow when using this filling machine?

A: Bottles are automatically conveyed to each station, filled using anti-drip nozzles controlled by a PLC system, and then sealed and moved onwardall at an adjustable speed of 20-60 bottles per minute, ensuring efficient, continuous production.Q: How does the multilingual HMI interface improve user experience?

A: The touchscreen human-machine interface (HMI) supports multiple languages, enabling operators from different regions to navigate settings and monitor machine status easily, reducing the risk of errors and increasing overall efficiency.Q: What safety features are integrated into the machine for operator protection?

A: Overload protection and an emergency stop button are built-in safety measures. They protect both operators and equipment by immediately halting machine operation during unexpected issues or emergencies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Volumetric Liquid Filling Machine

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free