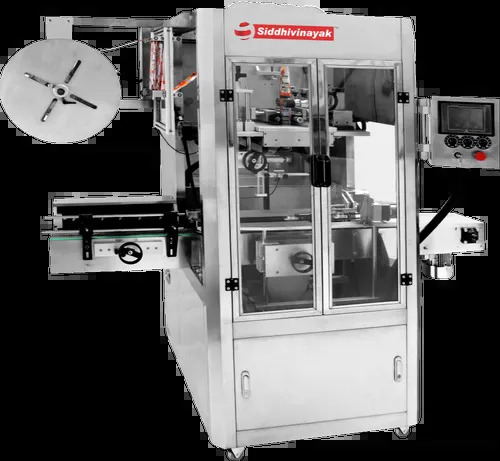

Shrink Sleeve Label Applicator

Price 600000.00 INR/ Unit

Shrink Sleeve Label Applicator Specification

- Product Type

- Shrink Sleeve Label Applicator

- Material

- Stainless Steel / Mild Steel

- Application

- Bottles, Containers, Cans, Jars

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Servo Motor Drive

- Accuracy

- 1 mm

- Power Source

- Electric

- Voltage

- 220-240 V AC, 50/60 Hz

- Weight (kg)

- Approx. 450 kg

- Dimension (L*W*H)

- 2400 mm x 950 mm x 1800 mm

- Capacity

- 60 to 300 BPM (Bottles Per Minute)

- Feature

- High Speed, Precise Positioning, Easy Sleeve Changeover, User-Friendly Interface

- Color

- Silver & Blue

Shrink Sleeve Label Applicator Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 1 Week

About Shrink Sleeve Label Applicator

Discover the Shrink Sleeve Label Applicator, an ephemeral solution crafted for high-speed industrial labeling. Top-rated by users for its precise 1 mm accuracy and meritorious operation, it accommodates diverse bottle shapesround, square, or ovalwith bottle diameters from 28 mm to 125 mm and label widths of 70-200 mm. The wondrous servo motor drive and PLC control ensure effortless, automatic performance. Safety features, user-friendly interface, and robust stainless steel construction mark this noteworthy applicator as a market leaderoffering the best price for exceptional quality in India and exported worldwide.

Superior Construction and Industrial Versatility

Engineered from stainless steel, the Shrink Sleeve Label Applicator is distinguished by its durability in demanding environments. Widely used by manufacturers, bottlers, and industrial packagers, it is trusted for consistent labeling across bottles, containers, cans, and jars. With a fully automatic operation, adjustable conveyor speeds, precise positioning, and high usability, it reliably handles round, square, and flat PET, HDPE, and glass bottles in large-scale production lines.

Flexible Payment Terms & Market Reach

Our proposal amount accommodates a range of flexible payments to suit diverse client needs. With swift shipment arrangements, your order arrives promptly and securely, ensuring minimal interruption to your workflow. Main export markets include Asia, Africa, and the Middle East, while domestically, the Shrink Sleeve Label Applicator is popular across India, empowering industries to streamline their labeling process with guaranteed efficiency and compliance.

Superior Construction and Industrial Versatility

Engineered from stainless steel, the Shrink Sleeve Label Applicator is distinguished by its durability in demanding environments. Widely used by manufacturers, bottlers, and industrial packagers, it is trusted for consistent labeling across bottles, containers, cans, and jars. With a fully automatic operation, adjustable conveyor speeds, precise positioning, and high usability, it reliably handles round, square, and flat PET, HDPE, and glass bottles in large-scale production lines.

Flexible Payment Terms & Market Reach

Our proposal amount accommodates a range of flexible payments to suit diverse client needs. With swift shipment arrangements, your order arrives promptly and securely, ensuring minimal interruption to your workflow. Main export markets include Asia, Africa, and the Middle East, while domestically, the Shrink Sleeve Label Applicator is popular across India, empowering industries to streamline their labeling process with guaranteed efficiency and compliance.

| Phase | Single phase |

| Voltage | 230 volt |

| Usage/Application | Industrial |

| Bottle Type | Round,Flat and Sqare Pet,Hdpe & Glass bottles |

| Speed | Up to 300 BPM |

| Capacity | 100bpm to 300bpm |

| Material | Stainless Steel |

| Type | Fully Automatic |

| Brand | Siddhivinayak Automation |

| Application | Industrial |

| Power Source | Electric |

| Automation grade | Automatic |

FAQs of Shrink Sleeve Label Applicator:

Q: How does the Shrink Sleeve Label Applicator ensure accurate label placement?

A: The machine utilizes a servo motor drive and PLC control system, delivering label positioning accuracy within 1 mm regardless of container shape or size.Q: What types and shapes of bottles can be labeled with this applicator?

A: It supports round, flat, and square bottles made from PET, HDPE, or glass, accommodating various sizes with a minimum diameter of 28 mm and maximum of 125 mm.Q: Where can this machine be effectively utilized?

A: This applicator is ideal for industrial bottling, food and beverage, pharmaceutical, and cosmetic production facilities requiring automated, high-speed labeling solutions.Q: What is the usage process for changing label sleeves?

A: The applicator is designed for rapid and easy sleeve changeover, minimizing downtime and facilitating uninterrupted, high-volume production.Q: What are the benefits of the Shrink Sleeve Label Applicators safety features?

A: Equipped with emergency stop buttons and protective safety covers, the machine ensures operator safety during operation, maintenance, and cleaning.Q: How is payment handled and when will shipment arrive after placing an order?

A: Payment terms are tailored according to the proposal amount discussed. Shipments are expedited post-confirmation, ensuring prompt arrival as per agreed schedules.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Shrink Sleeve Applicator Category

Automatic Shrink Sleeve Applicator

Price 1050000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : S.S.304

Drive Type : Electric

Power Source : Electric

Color : Silver

SS Automatic Shrink Sleeve Applicator

Price 1 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Metal

Drive Type : Electric

Power Source : Electric

Color : White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free