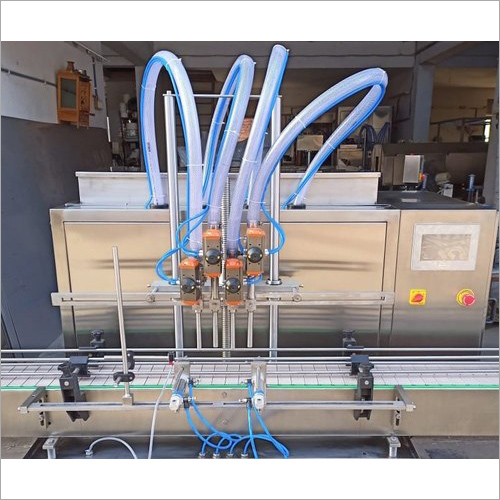

Milk Filling Machine

Milk Filling Machine Specification

- Packaging Material

- Plastic or Glass Bottles, Pouches

- Sealing Type

- Heat Sealing

- Production Capacity

- 1500-2000 Bottles/hour

- Seals Type

- Heat Seal

- Weight

- Approx. 400 Kg

- Driven Type

- Electric

- Application

- Beverage, Dairy, Milk Filling

- Power

- 2.0 KW

- Condition

- New

- Dimension (L*W*H)

- 1680 x 1350 x 1850 mm

- Voltage

- 220V/380V, 50/60Hz

- Contact Load

- Multi-head (2/4/6 Nozzles Optional)

- Accuracy

- 1%

- Sealing Length

- Customizable

- Filling Capacity

- 200 ml to 1000 ml

- Color

- Stainless Steel Finish

- Type

- Automatic Milk Filling Machine

- Packaging Speed

- Up to 2000 bottles per hour

- Sealing Speed

- 1500-2000 pouch/hr

- Automation Grade

- Automatic

- Air Pressure Requirement

- 0.4-0.6 MPa

- Bottle Size Range

- 200 ml to 1000 ml

- Control System

- PLC Controlled, Touch Screen Interface

- Body Material

- Food Grade SS304 Stainless Steel

- Noise Level

- 75 dB(A)

- Filling Heads

- 2, 4, or 6 Nozzles (as per model)

- After Sales Service

- Available

- Cleaning System

- Online CIP (Clean-In-Place) Compatible

- Filling Method

- Volumetric Piston or Gravity Filling

Milk Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2-4 Week

About Milk Filling Machine

This highly productive numerically controlled milk filling machine is capable of filling bottles within the pre set time limit for filling. Its automatic bottle counting function and leakage protected filling mechanism improves productivity without raising production cost. This stainless steel machine is capable of filling multiple bottles of milk simultaneously without compromising its production quality. Provided milk filling machine is equipped with silicon gel based tubes and PVC pump head. Digital display unit and control front panel of this machine have been specially designed to make this machine user friendly and application specific.

| Automation Grade | Automatic |

| Warranty | 1 Year |

| Model Name/Number | SVASF |

| Driven Type | Electric |

| Voltage | 230 AC |

| Power | Single Phase |

| Container Height | 50ml to 5 ltr |

| Change Parts Required | Yes |

| Output Per Hour | Up to 30-32 BPM |

| Air Pressure | yes |

| Filling Speed | Up to 30-32 BPM |

| Number Of Phases | 1 -Phase |

| Filling Accuracy | Accuracy +- 0.8 % or 0.5 ml in single doze |

| Filling Range | Servo & Volumetric |

| Filling Head | 4 |

| Usage/Application | Automatic |

| Brand | SVA |

| Country of Origin | Made in India |

Advanced Filling Technology

This milk filling machine features PLC-controlled operation with a touch screen interface, simplifying the filling process and maintaining accuracy within 1%. Operators can choose between volumetric piston or gravity-based filling, adapting to different types of milk and beverage products. Multi-head nozzles (2, 4, or 6) guarantee higher productivity, accommodating businesses with different production scales.

Hygienic and Durable Construction

Made from food-grade SS304 stainless steel, the machine is rust-resistant and easy to clean. Its compatibility with online CIP (Clean-In-Place) systems ensures that hygiene standards are met without the need for time-consuming disassembly, ideal for dairy and beverage manufacturers seeking efficient cleaning and maintenance routines.

Versatile Packaging and High Efficiency

Suitable for both plastic and glass bottles as well as pouches, the machine adjusts to various bottle sizes from 200 ml to 1000 ml. With customizable sealing lengths and a heat seal mechanism, it can process up to 2000 bottles per hour, meeting the demands of high-volume producers. The machine's automated functions reduce labor requirements and optimize packaging speed.

FAQ's of Milk Filling Machine:

Q: How does the milk filling machine ensure accuracy during the filling process?

A: The machine utilizes a PLC-controlled system with volumetric piston or gravity filling methods, achieving filling accuracy within 1%. This technology monitors and controls the filling volume for each cycle, ensuring precise and consistent results across all bottles or pouches.Q: What is the process for cleaning and maintaining the machine?

A: This milk filling machine is equipped with an online CIP (Clean-In-Place) compatible system, allowing automated internal cleaning without dismantling parts. Routine maintenance involves checking seals, nozzles, and the touch screen interface, making upkeep simple and minimizing downtime.Q: When should I consider using this machine for my dairy or beverage production?

A: This machine is ideal for businesses needing to fill between 1500 and 2000 bottles per hour and handle bottle or pouch sizes from 200 ml to 1000 ml. It is especially beneficial for dairy processors, beverage manufacturers, and large-scale suppliers looking for automation and high efficiency.Q: Where can the machine be installed and what are the requirements?

A: The machine is designed for factory or production hall environments with suitable electrical connections (220V/380V, 50/60Hz) and air pressure (0.4-0.6 MPa). Its compact dimensions (1680 x 1350 x 1850 mm) allow for flexible integration into existing production lines.Q: What kind of packaging materials can the machine handle?

A: The machine is compatible with both plastic and glass bottles, as well as pouches. The customizable sealing system and adjustable nozzle heads accommodate various packaging needs, supporting versatility in product presentation.Q: How does the automatic sealing process benefit my production line?

A: Featuring a heat seal system and customizable sealing lengths, the machine ensures leak-proof and hygienic packaging at high speeds, reducing manual intervention and improving overall production flow.Q: What after-sales services are offered for the milk filling machine?

A: After-sales support is available, including installation assistance, operational training, troubleshooting, and supply of spare parts, ensuring sustained productivity and minimizing machine downtime for all customers in India and abroad.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Capping Machine Category

Automatic Screw Capper Machine With Conveyor

Price 280000 INR / Unit

Minimum Order Quantity : 1 Unit

Automation Grade : Automatic

Condition : New

Color : Stainless Steel Finish

Automatic Single Head Screw Capping Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Automation Grade : Automatic

Condition : New

Color : Stainless Steel Finish

Automatic Screw Capping Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Automatic

Condition : New

Color : Stainless Steel Finish

Automatic Low Speed Bottle Unscrambler

Price 950000 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Yes

Condition : New

Color : Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS