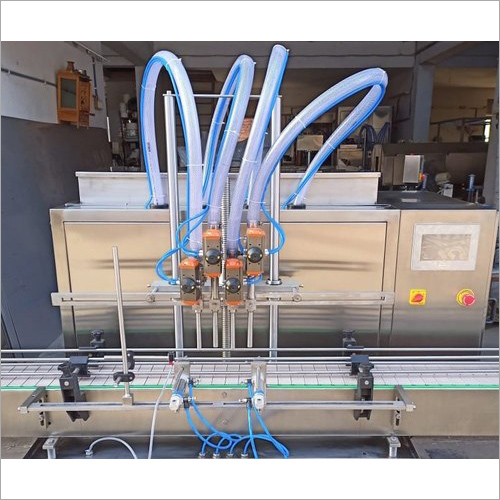

Automatic Single Head Screw Capping Machine

Automatic Single Head Screw Capping Machine Specification

- Driven Type

- Electric / Motorized

- Application

- Screw capping of bottles, containers, vials, jars

- Filling Capacity

- Up to 1000 ml containers

- Voltage

- 220V AC

- Type

- Automatic Single Head Screw Capping Machine

- Automation Grade

- Automatic

- Seals Type

- Screw Cap

- Weight

- Approx. 250 kg

- Sealing Type

- Screw sealing

- Packaging Material

- Plastic, Glass, PET, HDPE

- Packaging Speed

- 30 to 50 bottles per minute

- Sealing Length

- Adjustable as per container height

- Color

- Stainless Steel Finish

- Dimension (L*W*H)

- 1800 mm x 850 mm x 1600 mm

- Production Capacity

- 1500-3000 bottles/hour

- Power

- 1 HP, 220V, 50Hz

- Sealing Speed

- 30-50 bottles/minute

- Condition

- New

- Contact Load

- Standard, suitable for up to 5000 operations/day

- Accuracy

- 1% per cap

- Maintenance

- Low, Easy to Clean

- Safety Features

- Auto Stop for Jam/No Bottle, Safety Guard Available

- Cap Diameter Range

- 20 mm to 50 mm

- Change Parts Required

- Yes, for different bottle/cap sizes

- Control System

- PLC based with HMI Touch Screen

- Body Material

- Stainless Steel 304

- Cap Feeding System

- Automatic Vibratory Bowl or Elevator

- Bottle Height Range

- 50 mm to 300 mm

- After Sales Service

- Available

- Conveyor Speed

- Variable, with AC frequency drive

- Noisy Level

- Low Noise Operation (<70 dB)

- Operation Mode

- Continuous

Automatic Single Head Screw Capping Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2-4 Week

About Automatic Single Head Screw Capping Machine

Commercial Applications and Industrial Versatility

The Automatic Single Head Screw Capping Machine is an indispensable asset for commercial packing lines in pharmaceuticals, beverages, chemicals, and cosmetics. Its sublime design excels in medium- to large-scale plants, and can be seamlessly integrated into automated packaging sites. Suitable for factories, contract manufacturers, and exporters, it is engineered for continuous use across diverse industries, ensuring efficiency and integrity of product sealing with every cycle.

Sample Availability, Export Market Reach, and Delivery Commitment

Sample units for the Automatic Single Head Screw Capping Machine can be arranged for testing and quality verification before bulk purchase. With a robust packing & dispatch system, orders are promptly dispatched to main export markets including Asia, Africa, Europe, and the Middle East. Standard delivery time ranges from 2 to 4 weeks after order confirmation, ensuring customers can exchange requirements quickly and reliably.

FAQ's of Automatic Single Head Screw Capping Machine:

Q: How does the Automatic Single Head Screw Capping Machine operate?

A: The machine operates via a PLC-based control system with a user-friendly HMI touch screen, automatically feeding caps using a vibratory bowl or elevator. Bottles are sealed consistently, with adjustable speed and continuous operation for efficiency.Q: What types of bottles and caps are compatible with this capping machine?

A: It accommodates a wide range of bottle materials including plastic, glass, PET, and HDPE, with cap diameters from 20 mm to 50 mm and bottle heights from 50 mm to 300 mm. Change parts allow adaptation to different bottle and cap sizes.Q: Where is this machine commonly used?

A: This machine is commonly deployed in manufacturing plants for pharmaceuticals, cosmetics, food and beverages, chemicals, and more, making it ideal for commercial, industrial, and export-oriented operations.Q: When will my order be dispatched, and what is the typical delivery timeframe?

A: Orders are packed and dispatched swiftly after confirmation. The usual delivery period is 2-4 weeks, depending on requirements and location, ensuring timely fulfillment for customers worldwide.Q: What safety features are included in this capping machine?

A: Key safety features include auto stop for jam or no-bottle situations, an integrated safety guard, and easy-to-clean design, supporting low-noise operation and reducing operational risks.Q: How does this machine maintain precision and efficiency during use?

A: The machine boasts an accuracy of 1% per cap, continuous mode operation, variable conveyor speeds, and sealing speeds of 30-50 bottles per minute, ensuring both reliability and peak production capacity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Capping Machine Category

Milk Filling Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Weight : Approx. 400 Kg

Sealing Speed : 15002000 pouch/hr

Contact Load : Multihead (2/4/6 Nozzles Optional)

Automatic Multi Head Screw Capping Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Weight : Approx. 550 kg

Sealing Speed : Up to 120 caps per minute

Contact Load : 10A 240V AC

Automatic Screw Capping Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Weight : Approx. 300 kg

Sealing Speed : 3060 bottles per minute

Contact Load : Standard

Bottle Neck Sleeve Shrinking Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Weight : Approx. 55 kg

Sealing Speed : 5 25 meters/min

Contact Load : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free