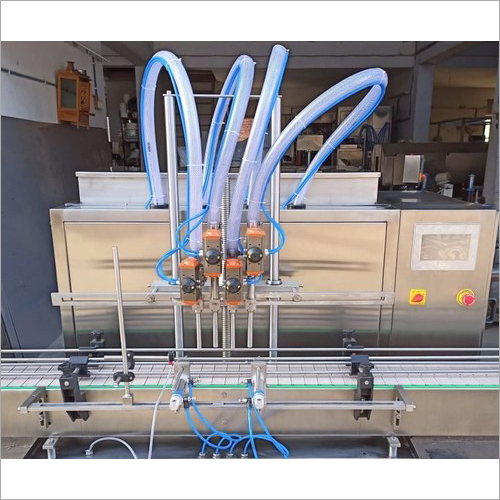

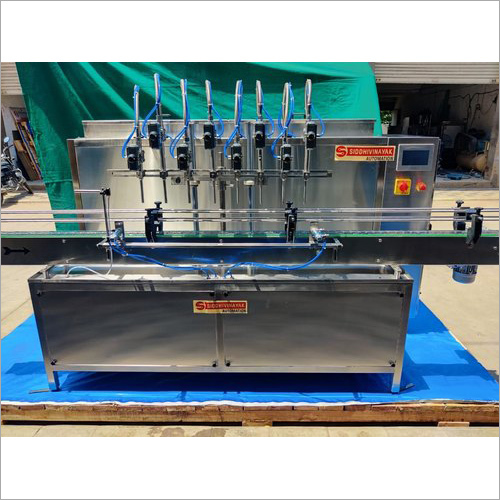

Automatic Four Head Liquid Filling Machine

Automatic Four Head Liquid Filling Machine Specification

- Sealing Type

- Cap Sealing

- Contact Load

- High duty, stainless steel contact parts

- Filling Capacity

- 50 ml to 1000 ml (per operation)

- Packaging Speed

- 1500-3600 bottles/hour

- Production Capacity

- Up to 3600 bottles/hour

- Condition

- New

- Power

- 1.5 kW

- Sealing Speed

- Up to 60 bottles/min

- Packaging Material

- Liquid

- Voltage

- 220V/440V, 50 Hz

- Driven Type

- Electric

- Automation Grade

- Automatic

- Color

- Stainless Steel Finish

- Weight

- Approx. 350 kg

- Sealing Length

- Customizable based on container

- Seals Type

- Screw/Cap Sealing

- Application

- Liquid Filling in bottles/containers

- Dimension (L*W*H)

- 2000 mm x 900 mm x 1600 mm

- Accuracy

- +/- 1%

- Type

- Automatic Four Head Liquid Filling Machine

- Bottle Height Supported

- 50 mm to 300 mm

- Conveyor Length

- 8-12 feet (customizable)

- Noise Level

- <75 dB

- Safety Features

- Emergency stop, interlocks

- Material of Construction

- Stainless steel (SS304/SS316)

- Nozzle Count

- Four heads (synchronised filling)

- Changeover Time

- Less than 20 minutes

- Suitable Liquid Viscosity Range

- Low to medium viscosity

- Bottle Diameter Supported

- Up to 100 mm

- Filling Method

- Volumetric piston or gravity filling

- Control System

- PLC Based with touchscreen HMI

- Air Pressure Required

- 6 kg/cm² (for pneumatic operations)

- Operation Mode

- Continuous

Automatic Four Head Liquid Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2-4 Week

About Automatic Four Head Liquid Filling Machine

| Automation Grade | Automatic |

| Warranty | 1 Year |

| Model Name/Number | SVASF |

| Driven Type | Electric |

| Voltage | 230 AC |

| Power | Single Phase |

| Container Height | 50ml to 5 ltr |

| Change Parts Required | Yes |

| Output Per Hour | Up to 30-32 BPM |

| Air Pressure | yes |

| Filling Speed | Up to 30-32 BPM |

| Number Of Phases | 1 -Phase |

| Filling Accuracy | Accuracy +- 0.8 % or 0.5 ml in single doze |

| Filling Range | Servo & Volumetric |

| Filling Head | 4 |

| Usage/Application | Automatic |

| Brand | SVA |

| Country of Origin | Made in India |

Advanced Synchronized Four-Nozzle Filling

This machine utilizes four synchronized filling heads, facilitating simultaneous accurate filling of multiple bottles. The volumetric piston or gravity methodology ensures steady output, while high-quality stainless steel construction maintains hygiene. With a fill range between 50 ml and 1000 ml, it handles various container sizes with seamless efficiency, making it suitable for diverse bottling operations.

User-Friendly Touchscreen Controls

A PLC-based control system with an intuitive touchscreen HMI allows operators to manage machine settings efficiently. Quick changeover times, customizable conveyor lengths, and clear interface simplify production adjustments, ensuring minimal downtime and flexible operation for different bottle specifications without the need for complex manual intervention.

Safety and Reliable Operation

Built with operator safety in mind, this liquid filling machine incorporates emergency stop functions and interlocks, as well as maintaining low noise levels under 75 dB. The robust stainless steel body ensures durability while high-duty contact parts guarantee long-term reliability, offering continuous operation for demanding industrial environments.

FAQ's of Automatic Four Head Liquid Filling Machine:

Q: How does the Automatic Four Head Liquid Filling Machine manage different bottle sizes?

A: The machine accommodates bottle diameters up to 100 mm and heights ranging from 50 mm to 300 mm. Its adjustable features allow quick adaptation to various container specifications, and changeover between different bottle sizes typically takes less than 20 minutes.Q: What liquids can be filled with this machine, and what is the suitable viscosity range?

A: This machine is ideal for packaging low to medium viscosity liquids, including water, beverages, cosmetic fluids, and pharmaceutical solutions. Its volumetric piston or gravity filling options provide versatility for different product types.Q: When is the recommended time to perform a changeover between products?

A: Changeover should be performed whenever switching to a new liquid, bottle size, or packaging material. The process is streamlined and typically completed within 20 minutes due to the machine's ergonomic design and user-friendly controls.Q: Where is this machine commonly used, and who are its main users?

A: This liquid filling machine is widely used in beverage, pharmaceutical, chemical, and cosmetic manufacturing facilities. Typical users are exporters, manufacturers, and suppliers requiring automated high-capacity filling solutions in India and globally.Q: What is the benefit of the PLC-based touchscreen HMI control system?

A: The PLC-based touchscreen HMI provides operators with easy access to machine settings and diagnostics, enabling real-time monitoring and efficient adjustments. This enhances accuracy, reduces downtime, and improves overall productivity.Q: How does the machine ensure safety and reliability during operation?

A: Safety is maintained through integrated emergency stop features, interlocks, and a noise level below 75 dB. The machine's durable stainless steel construction and high-duty contact parts ensure consistent, reliable performance in continuous production environments.Q: What is the production capacity and accuracy of the machine?

A: The machine can achieve a packaging speed of up to 3,600 bottles per hour with a sealing speed of 60 bottles per minute. It provides high filling accuracy with a variance of only +/- 1% per operation, ensuring consistent output and minimal waste.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Capping Machine Category

Milk Filling Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 400 Kg

Sealing Length : Customizable

Seals Type : Heat Seal

Dimension (L*W*H) : 1680 x 1350 x 1850 mm

Automatic Screw Capper Machine With Conveyor

Minimum Order Quantity : 1 Unit

Weight : Approx. 350 kg

Sealing Length : Customizable as per bottle size

Seals Type : Screw Cap

Dimension (L*W*H) : 2200 mm x 900 mm x 1600 mm

Servo Liquid Filling Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 450 kg

Sealing Length : Customizable as per bottle sizes

Seals Type : Bottle capping (threaded, press cap, ROPP as per compatibility)

Dimension (L*W*H) : 2100 mm x 950 mm x 1700 mm

Servo Base Liquid Filling Machine

Price Range 40000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS